Splicer Auto Index System

Upgrade Application

Applicable to PLC-controlled Model I splicers.Upgrade Description

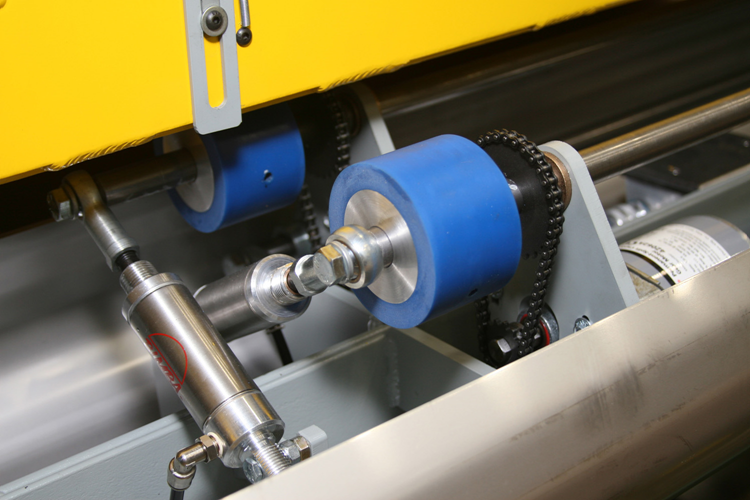

The Auto Index System upgrade addresses the problem of missed splices caused by improper positioning of the paper or loose paper edges. With this upgrade, the operator prepares the splice the same way, but does not have to index the web. Instead, the head is brought into the ready position and a pair of wheels comes into contact with the new web . The wheels automatically index the web to the proper position. The operator then removes the slack between the prepared roll and the head. If there is slack on one edge of the new web, the operator pushes a button causing the wheels to run in reverse thereby removing the slack from the edge.Upgrade Benefits

- Improves splicer reliability by precisely positioning the new web at the splice nip roll centerline

- Eliminates a baggy web edge from the prepared roll to ensure optimum reliability

- Prevents occasional missed splices due to operator incorrectly preparing splices

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)