Shear Scrap Divert Options

Upgrade Applications

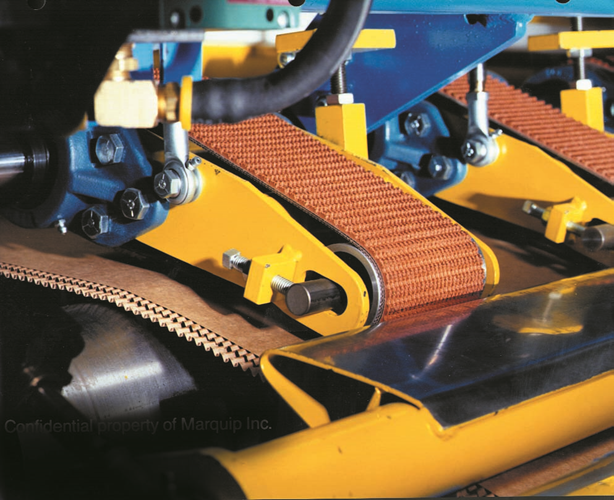

Applicable to Dual Rotary and Rotary (Black Belt) Shears.Upgrade Description

Remote Scrap Divert:

Allows the Wet End operator to manually segment and divert scrap board prior to reaching the Shear. The operator pushes a button as scrap board passes, and then presses the same button when good board reaches the same reference point. The segment of the scrap board between the two push button depressions is tracked through the Doublefacer and then diverted at the Shear.

Dry Spot Divert:

Provides automatic diversion of board whenever a pre-set limit of corrugator stop time is exceeded. The segment of the board between the glue applicator roll and the hot plate section at the time will be automatically diverted at the Shear.

Hot Plate Scrap Divert:

Provides automatic diversion of board in the hot plates of the corrugator whenever a pre-set limit of corrugator stop time is exceeded. All board that had been in the hot plates while the corrugator was stopped will be automatically diverted at the Shear.

Upgrade Benefits

- Increases uptime on the Dry End.

- Decreases downtime as a function of reduced paper jams on the Dry end due to bad board or loose back.

- Improves stack quality because only good board is placed onto the Stacker

– eliminates stacks that tip over in the stack lift bay area that may cause corrugator downtime - Significantly reduces the need for Dry End operator to operate the shear divert sequence to divert bad board.

- Gives shear divert operations to the Wet End operator and takes advantage of the Wet End operator’s proximate location to determine board quality.

- Reduces Dry End and Stacker operators’ workload, allowing them to do other tasks that are more critical, such as quality control.

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)