Model I Stacker Controls

Upgrade Application

Applicable to all Model I stackersUpgrade Description

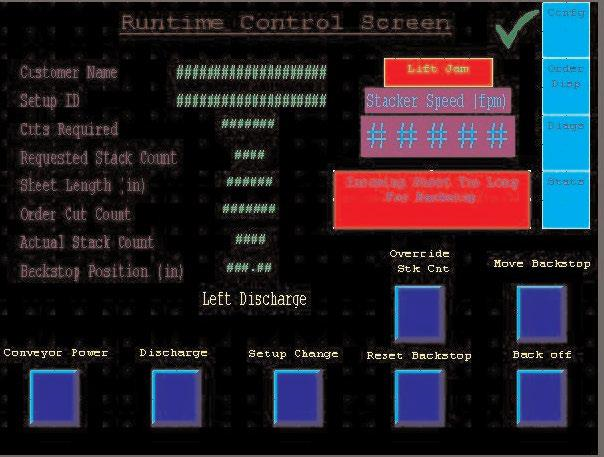

Replaces obsolete 5TI programmable logic controllers with Allen-Bradley SLC 500 series platforms and provides Allen-Bradley PanelView 1000 operator interface with color touchscreen at the main console. The new front end computer will fit into the existing front end console.

Replaced Components:

- 5 TI PLC’s and input/output modules

- Existing front end computer keyboard

- Conveyor speed card

- Totalizers and assorted pushbuttons on console

- Backstop card

- Prewarn Card

Upgrade Benefits

- Extends the productive life of the stacker

- Enhances reliability and reduces risk of obsolescence through replacement of obsolete and custom, proprietary, 20-year-old controls technology with state-of-the-art, standard industrial controls

- Reduces component count and failure potential while simplifying troubleshooting

- Reduces downtime via online diagnostics

- Eliminates “pot tweaking” as a function of extensive on-line configuration

- Increase productivity via open controls platform which allows for control enhancements

- Allows sourcing of replacement parts from local vendors

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)