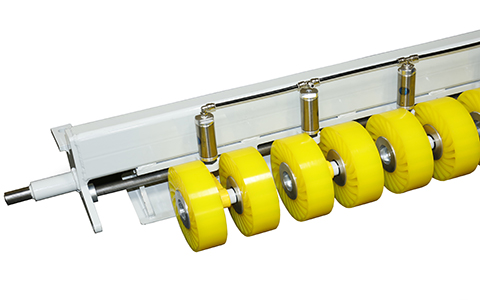

Knife Shingling Exit Nip Air Cylinder

Upgrade Application

Applicable to any Model II or Model III KnifeUpgrade Description

Provides improved board control and shingle quality by increasing the exit nip force and zero-crush wheel stability. Includes a new exit hold down assembly with a combination of shocks and air cylinders, torsion springs, bearings, zero crush wheels, and exit infeed pan.Upgrade Benefits

- Improves board control for increased stack quality

- Decreases knife and stacker shingling area jams which decreases downtime and increases run ability of corrugator.

- Improves overall run ability of all board characteristics through better board control

- Exit infeed pan helps direct leading edge of sheet into the exit roll nip at the correct nip point height.

- Allows Exit Nip force to be adjusted for better control of sheets. This is particularly useful for high speed, heavy board or micro-flute applications.

- Long lasting Air cylinder reduces maintenance time

- Kit pre-assembled for easy installation

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)