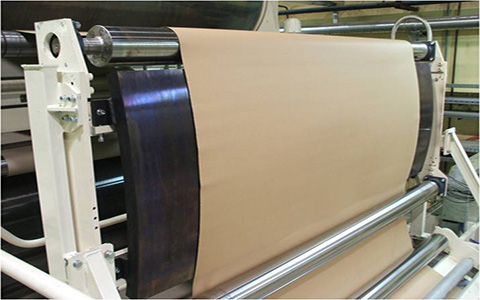

Infusion Curved Hot Plate

Upgrade Application

Applicable to almost all Singlefacers and Glue Machines.Upgrade Description

The Infusion Curved Hot Plate is designed to be easily installed in a variety of locations on the corrugator:

- Over the Glue Unit to Precondition the fluted side of the singleface web.

- Under (or before or after) the glue unit heat the doubleface liner.

- Bridge or floor mounted to precondition medium or preheat the liner prior to the singlefacer.

Replace non-infusion curved plates in Vanguard Singlefacers. The curved hot plate utilizes patented Infusion technology to heat and precondition the web for optimum performance and runnability.

Upgrade Benefits

- More rapid transfer of heat to the moving paper surface

- Easily installed - small compact package

- Self-limiting temperatures - paper will not overheat even at low speeds

- Paper heating independent of web tension Productivity Improvements

- Higher operating speeds

- Better glue bond can be achieved with less glue

- Improved flute formation - reduced fracturing and/or highs and lows

- Improved runnability with all medium grades

- Can be used to facilitate special processes such as dual arch and waxed or coated paper

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)