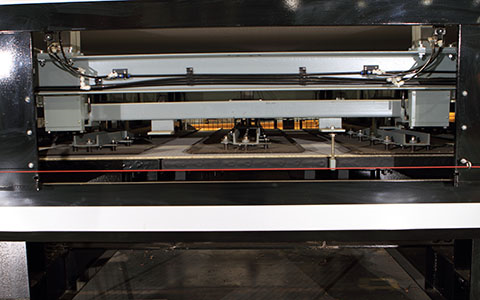

Doublefacer Gun Drilled Hot Plates

Upgrade Application

Applicable to most doublefacers.Upgrade Description

Gun drilled hot plates replace existing hot plates to permit more effective heat transfer, while maintaining a higher surface temperature. This increased surface temperature minimizes plate deflection and edge crush. Board quality also improves from this temperature increase. MarquipWardUnited will provide standard 25 mm (1 in) steam inlet and outlet. Customer is responsible for steam piping and installation.An Infusion-Capable hot plate option adds InfusionTM steam passages to provide even greater process control in the doublefacer.

Upgrade Benefits

- Rapid transfer of heat to the running web allows for finer heat control

- Hotter plates allow faster run speeds

- Flatter hot plates reduces board crush

- Preserves liner moisture for improved warp control and reduced liner cracking

- Paper heating independent of web tension

- Improved warp control

- Compatible with shoe or roller hold down systems

- Gun drilled hot plates resist twisting or deforming due to heat transfer

- Plate designed to fit into existing mounting locations

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)