TIP C 2211 Servo Drive System for Ream Reject Unit type „Alfredomat“

Machine Model for Improvement

Description of Improvement

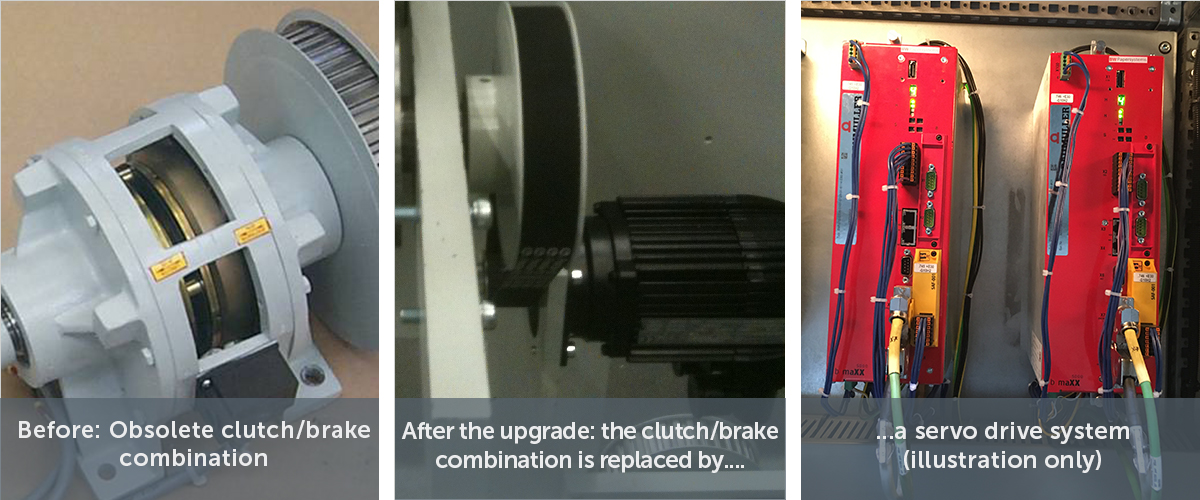

The existing clutch/brake combination in the ream reject unit type “Alfredomat” is obsolete. If this clutch/brake combination should fail or break, extensive downtime would result.

This upgrade replaces the “Stromaloom” control unit and the clutch/brake combination with a modern, state-ofthe-art servo drive system. This system is a stand-alone system, independent of other drive upgrades (e.g. AMK upgrades for the V1 & V2 drives at the ream discharge). Full functionality of the unit is restored with original specification remaining unaltered. There is no change to the original ream reject speed.

As only the obsolete parts are replaced, this upgrade eliminates the risk and costs of unplanned downtime due to obsolescence for minimum investment.

Benefits

- Restores reliable functioning, minimizes unplanned downtime through replacement of all obsolete parts

- Minimum investment upgrade independent of further drive upgrades

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)