Shear Simplified Diverter for Increased Reliability

Upgrade Applications

Applicable to all Dual Rotary Shears that currently have a belt style divert system.

Upgrade Description

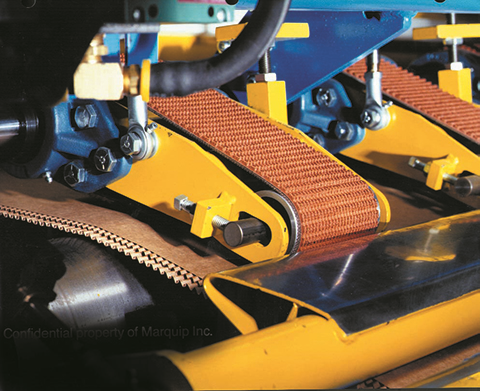

The individual belt diverter systems are removed and replaced with a simple solid torque shaft, no-crush wheel design.Upgrade Benefits

- Machine maintenance is significantly reduced

- The number of moving parts and wear items (belts, bearings, shocks) is dramatically reduced. Maintenance cost for both hardware and labor is reduced

- Only one pneumatic cylinder is needed for the single torque shaft versus one cylinder per diverter belt with

- The simplified diverter will divert sheets more reliably than the belted diverter design

- Increases corrugator uptime by providing more reliable shear diverting

- Nip Roll design provides positive nip to reliably drive looseback into scrap cart

- Common parts with MarquipWardUnited Knife reduce parts inventory

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)