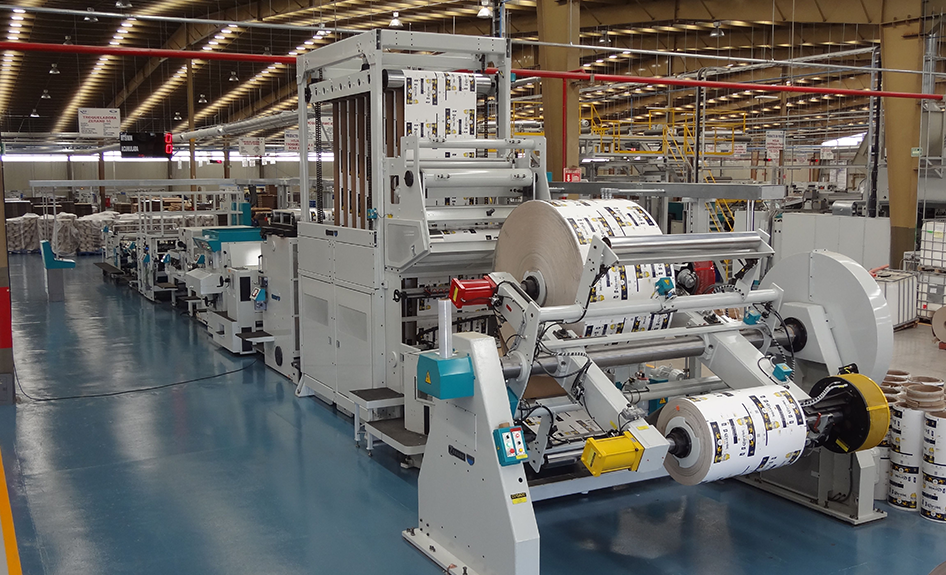

Zerand Unwinder Unit

Product Description

Efficiently feed printed or unprinted web from reel to printing and converting operation. The two position turnover allows for continuous operation of the line by rotating new rolls into positions and expiring rolls to the unload position to remove the empty core and begin loading immediately. The Pneumatic segmented disc brakes are specially designed for current paper board industry and customer caliper board. (.010 - .040 pt.) The Standard Unwinder uses BWP Zerand Electronic “Tension Control System” for precise control though out roll diameter.

Product Features

Two position 360 degree Turnover

Pneumatic segmented disc brakes

Precise Control

Unwound Preference

- 8 in. (2134 mm) for 40, 48 in. and 55 in. web

- 72 in (1830 mm) for 22 in. 26 in. and 32 in. web

- Maximum Speed 1500 FPM (450 M/MIN)

- Two position 360° turnover

- +/- 4 in. (100 mm) side lay control

- Core Diameter: 6 in. to 12 in.

- Spindle Control: Pneumatic segmented disc brakes

- Roll to roll laser alignment

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

a2a25e0f-43cd-43f0-9c3f-a5cc11fbcc29.jpg?sfvrsn=4dd9e7f_1)

359d5a13-484b-4d53-ac6f-d25f42158726.jpg?sfvrsn=c8dd9e7f_1)

.jpg?sfvrsn=a0dd9e7f_1)