P 35-49 Fully Automatic Binding Machine

Product Description

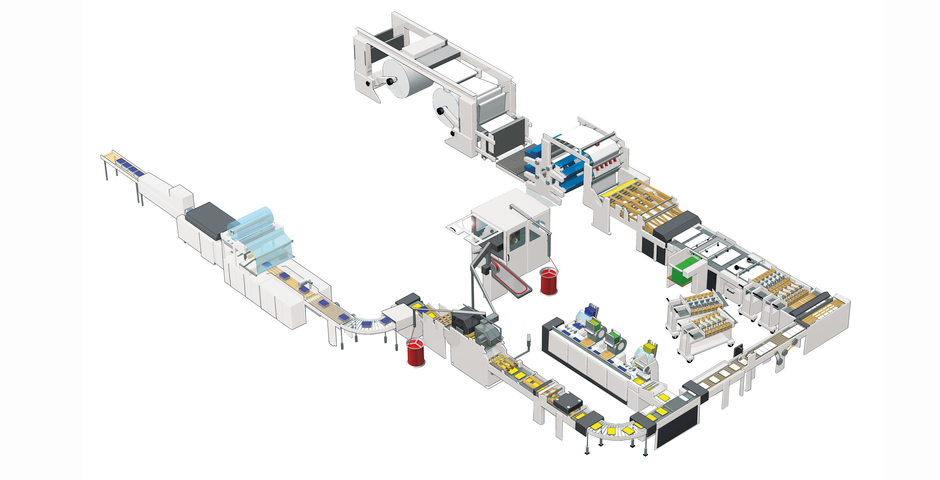

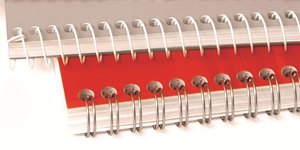

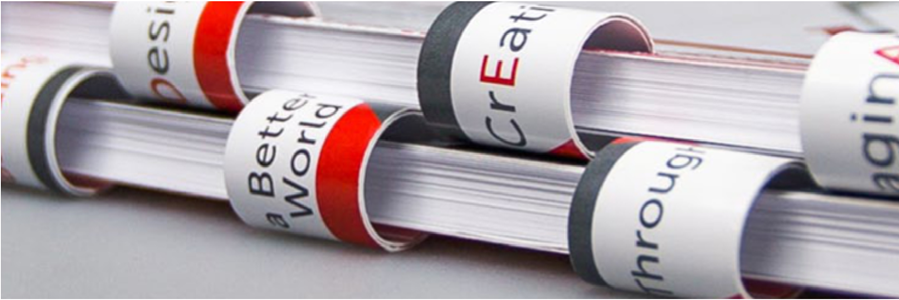

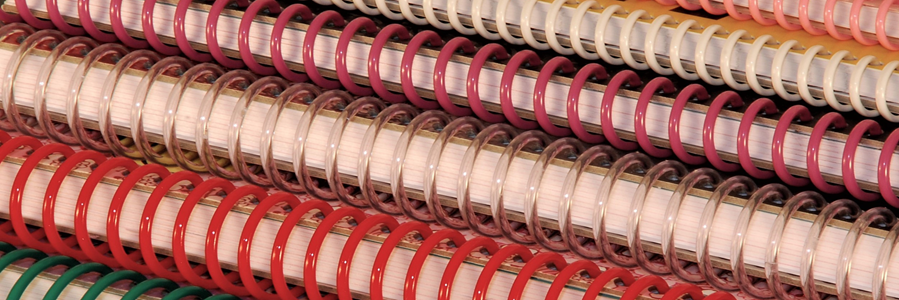

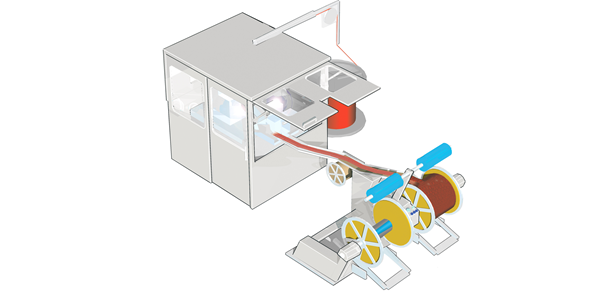

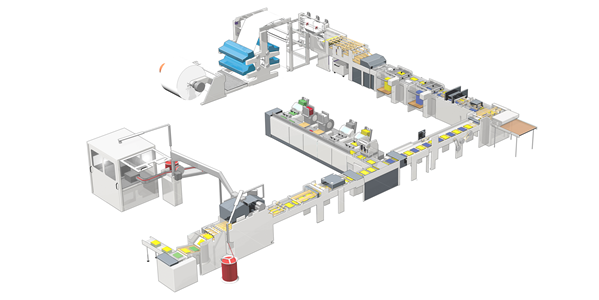

The fully automatic P 35-49 Binding Machine is a highly sophisticated solution for the fabrication of steel spiral and double-wire stationery products. It is optimally used for large runs, from paper reel to the finished product. Basic machine consists of one reel stand, 2/2 flexo ruling, cross cutting, counting, flexible cover feeding, punching and separating, collating, 90° transfer, spiral and/or double-wire binding and delivery in shingles.

Product Features

Fully Automatic Binding Machine for Steel Spiral and Double-Wire Products

Large Runs

Efficiency

Upgrades

Time Saving

| Imperial | Metric | ||

|---|---|---|---|

| Web speed | max. | 1640 fpm | 500 mpm |

| Paper reel width 5-up | max. min. | 44.5 in. 24 in. | 1130 mm 600 mm |

| Paper reel diameter | max. | 60 in. | 1525 mm |

| Paper weight | max. min. | 54 lbs 34 lbs | 80 g/m2 50 g/m2 |

| Printing circumference | max. min. | 28 1/2 in. 10 3/4 in. | 720 mm 270 mm |

| Adjustment of printing length | 1/4 in. (1/8 in.) | 5 (2,5 mm) | |

| Cutting frequency | max. | 5x1600 = 8000/min | |

| Number of partial layers | min. | 2 | |

| Punching cycles paper | max. | 5x80 = 400/min | |

| Punching cycles feeder section | max. | 120/min (160/min) | |

| Binding cycles 1-up | max. | 60/min | |

| Binding cycles 2-up | max. | 2x60 = 120/min | |

| Bound edge 1-up Machine without separation cut unit | max. min. | 13 in. 8 1/4 in. | 330 mm 210 mm |

| Bound edge 1-up Machine with separation cut unit | max. min. | 13 in. 6 5/16 in. | 330 mm 160 mm |

| Bound edge 2-up Machine with separation cut unit | max. min. | 6 5/16 in. 4 1/8 in. | 160 mm 105 mm |

| Unbound edge | max. min. | 13 in. 5 3/4 in. | 330 mm 148 mm |

| Binding cycles (extra width binding drum) | max. min. | 2x45 = 90/min (A4 and similar) 3x40 = 120/min (A5 and similar) | |

| Binding cycles (double head binding drum) | max. min. | 2x60 = 120/min (A4 and similar) 2x60 = 120/min (A5 and similar) | |

| Product thickness steel spiral | max. min. | 1 3/16 in. 5/64 in. | 30 mm 2 mm |

| Diameter steel spiral | max. min. | 1 3/4 in. 5/16 in. | 44 mm 8 mm |

| Product thickness double wire | max. min. | 3/4 in. 5/64 in. | 20 mm 2 mm |

| Diameter double wire | max. min. | 1 in. 1/4 in. | 25,4 mm 6,35 mm |

Please contact us for more information.

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

a2a25e0f-43cd-43f0-9c3f-a5cc11fbcc29.jpg?sfvrsn=4dd9e7f_1)

359d5a13-484b-4d53-ac6f-d25f42158726.jpg?sfvrsn=c8dd9e7f_1)

.jpg?sfvrsn=a0dd9e7f_1)